Tech-Sonic®

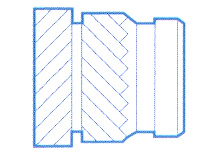

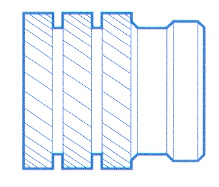

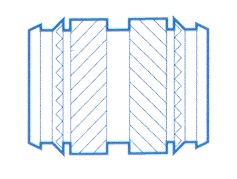

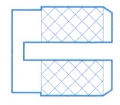

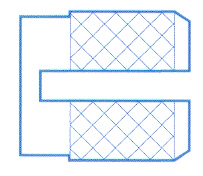

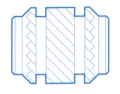

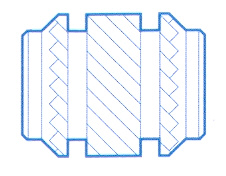

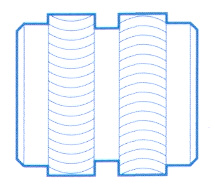

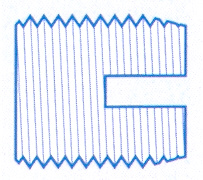

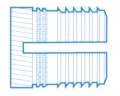

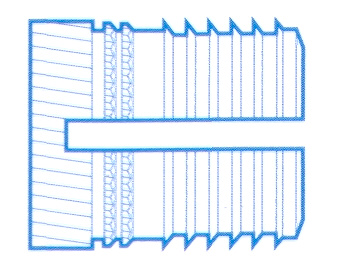

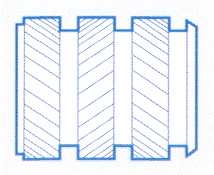

TEC features an unique combination of opposed knurls and knurled vanes providing increased performance levels, Installation is simplified by the symmetrical nature of the insert, eliminating the need for orientation during automated or hand feeding.